Temperature reduction achievable using indirect evaporative cooling and direct evaporative cooling.

Indirect evaporative cooling calculation.

Pmi evaporative cooling sizing calculator.

Start by selecting the a geographic location the cooler will be used in and then cooler model.

Moisture is not added to the primary air and.

Over the years we have designed systems with eer s exceeding 100.

The technology can be applied in numerous applications including data centers factories livestock and greenhouses please refer to our industry and product pages for more information on how munters evaporative cooling technologies can provide reliable cost.

Refine your configuration by adjusting static pressure desired indoor temperature air change method and ceiling.

The dry bulb temperature is reduced.

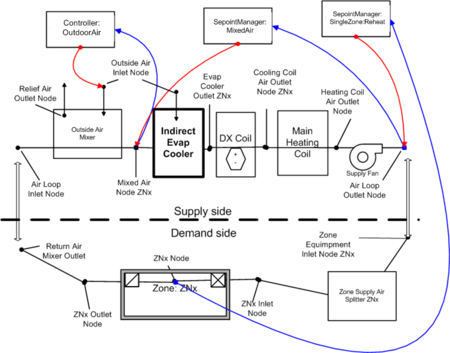

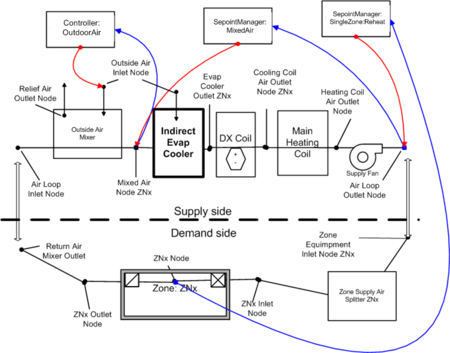

Indirect evaporative cooling systems.

In the process the air is cooled by 2 5 k per g of water absorbed per kg of air.

The secondary air stream is then used to cool down the primary air in a heat exchanger.

Indirect evaporative cooling uses the sump water which is close to the wet bulb temperature of the atmospheric air.

Use the calculator below to determine the appropriate cooler sizing based on your needs.

42 degrees c 23 5degrees c x 7 13 degreesc.

Direct and indirect evaporative cooling strategies.

In the indirect evaporative cooling system a secondary air stream is cooled down by evaporating water.

Our indirect evaporative cooling allows engineers and owners to get the efficiency benefit of water evaporation without concern for water carryover into the building.

The wet bulb temperature is reduced.

Energy labs has been building indirect evaporative cooling for over 30 years.

First calculate the dry bulb and wet bulb temperatures achievable with indirect evaporative cooling.

For steam humidifiers this energy typically comes from the electricity or gas being used to boil the water.

The elevated relative humidity after direct evaporative cooling is reduced by.

In indirect evaporative cooling the exhaust air removed from the building is humidified as closely as possible to the 100 saturation point.

To evaporate 1kg of water into an atmosphere 680w of energy is required.

Direct and indirect evaporative cooling are extremely energy efficient negating the need for compressors in the cooling cycle.