Primary mechanical shoe external roofs dt p1 read more.

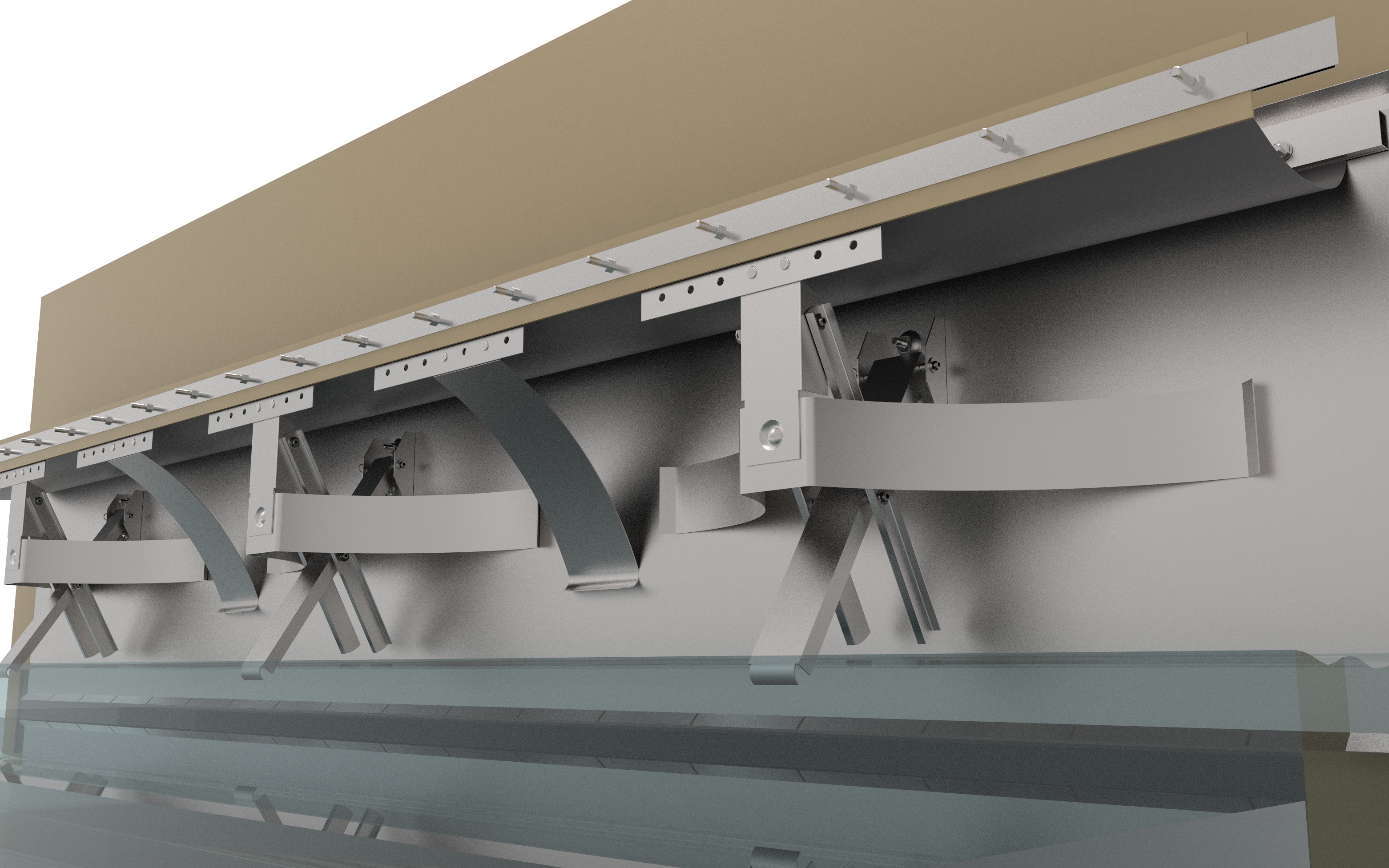

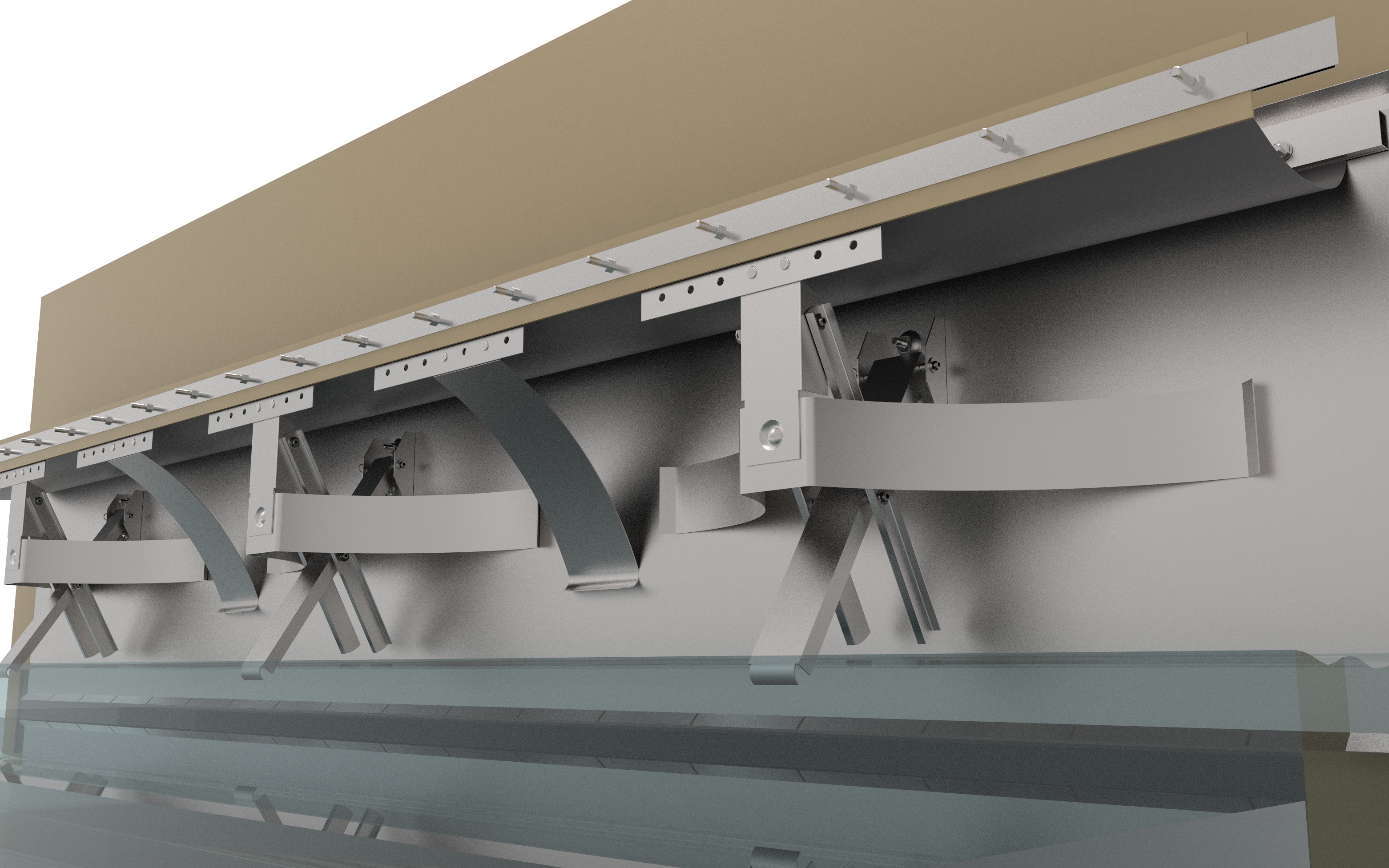

Internal floating roof mechanical shoe seal.

B a mechanical shoe seal and a secondary seal.

Primary mechanical shoe internal roofs dt p2.

Hmt seals are well known as leading the industry in design quality craftsmanship durability and non.

Custom shoe widths from 16 to 24 to meet the weight requirements of shallow steel roofs.

Mechanical shoe seals by their nature are liquid mounted and both tube.

Sandborn offers a ten year anti sinking warranty on our full contact floating roof systems.

Hmt offers a full line of primary and secondary seals for both internal and external floating roof tanks.

Hmt seal systems are customized for each specific tank with a variety of configurations component sizes and material options available to handle any application and stored product.

However some localities require a secondary seal on a covered floating roof if the primary seal is a vapor mounted seal.

The mini shoe has excellent chemical compatibility for nearly any product stored in a floating roof tank when combined with hmt s ptfe laminated flouropolymer vapor barrier fabric.

The patented allentech stainless steel mechanical shoe with its teflon vapor barrier is the only shoe seal specifically designed for aluminum internal floating roofs.

The mini shoe primary shoe seal was developed for steel internal floating roofs where tight rim spaces are encountered.

Secondary seals are normally required for external floating roof tanks and may or may not be required when an external roof covers the floating roof.

Rim seal options include the double wiper seal seen here the mechanical mini shoe seal or the combination shoe seal with secondary wiper seal for maximum efficiency.

The mini shoes are designed to fit on pan floating roofs with 15 or less of rim space.

Ii external floating roof.

We have designed and developed our own unique mechanical shoes for internal and external roofs based on our extensive experience of the industry.

An efr shall be equipped with one of the seal configurations listed in paragraphs a 1 ii a and a 1 ii b of this section.

Hangers are applied to the top and bottom of the shoe.

It offers a 25 year design life and excellent overall performance because of its resistance to most chemical products and ability to stand up to extreme temperature variations.

Mesa seal materials for metallic shoe seal systems are designed with superior abrasion and chemical resistance to ensure long service lives.

The upper end of the shoe s shall extend a minimum of 61 centimeters 24 inches above.

The mss p ptg1 mini shoe is adaptable to steel internal floating roofs.