A tig welder needs a filler rod to provide the welding bead when joining two pieces of metal together tig welding produces no sparks or spatter because only the necessary amount of filler metal is added to.

Identification tig welding filler rod chart pdf.

Online training for the welding gases and safety industry.

As a general rule of thumb tig likes dcen while stick welding likes dcep.

The base material and filler metal cross reference guide suggestions are based on joining of the same material to itself.

Www lincolnelectric eu welding consumables product catalogue cc05 16 www lincolnelectric eu customer assistance policy the business of lincoln electric europe is manufacturing and selling high qualit y welding equipment consumables and cutting equipment.

7018 required better rod control but does provide the strongest weld for heavy stress situations and also the smoothest weld for ornamental type products.

Table of contents tig torch connection diagrams gas cooled torches 3 water cooled torches 3 characteristics of current types for tig welding dc straight polarity 4 dc reverse polarity 4 ac high frequency 4.

When joining different material specifications grades classes and or types together engineering and fabrication judgment must be used in the application s the information contained or otherwise referenced herein is presented only as typical without.

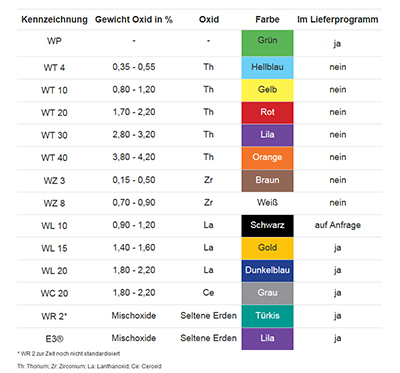

6correct torch and rod positioning selecting the correct torch nozzle gas lens benefits typical manual gta tig welding parameters aluminum titanium magnesium stainless steel deoxidized copper low alloy steel trouble shooting guide for gta tig welding excessive electrode consumption erratic arc inclusion of tungsten or oxides in weld.

This guide provides matching strength filler metal options.

These factors include but are not limited to the type of steel type of weld loading on the welded joint applicable codes level of preheat level of restraint position of welding condition of the steel and service conditions.

With tig welding the filler wire is always added to the joint with the opposite hand which gives you full control over the deposit rate and weld size.

Filler metal is selected for a specific application.

Puddle to work with.

The most common rod for stainless steel is 308 which works for base metals that are classified as either 304 or 308 using the aisi standard.

Either running straight or with a side to side motion the arc needs to be maintained on the leading edge of the puddle.

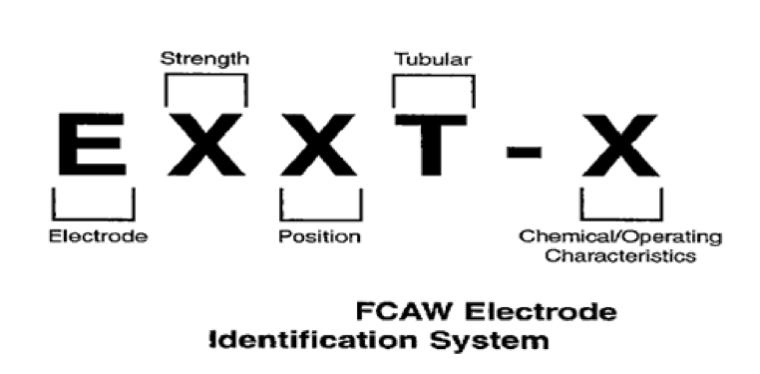

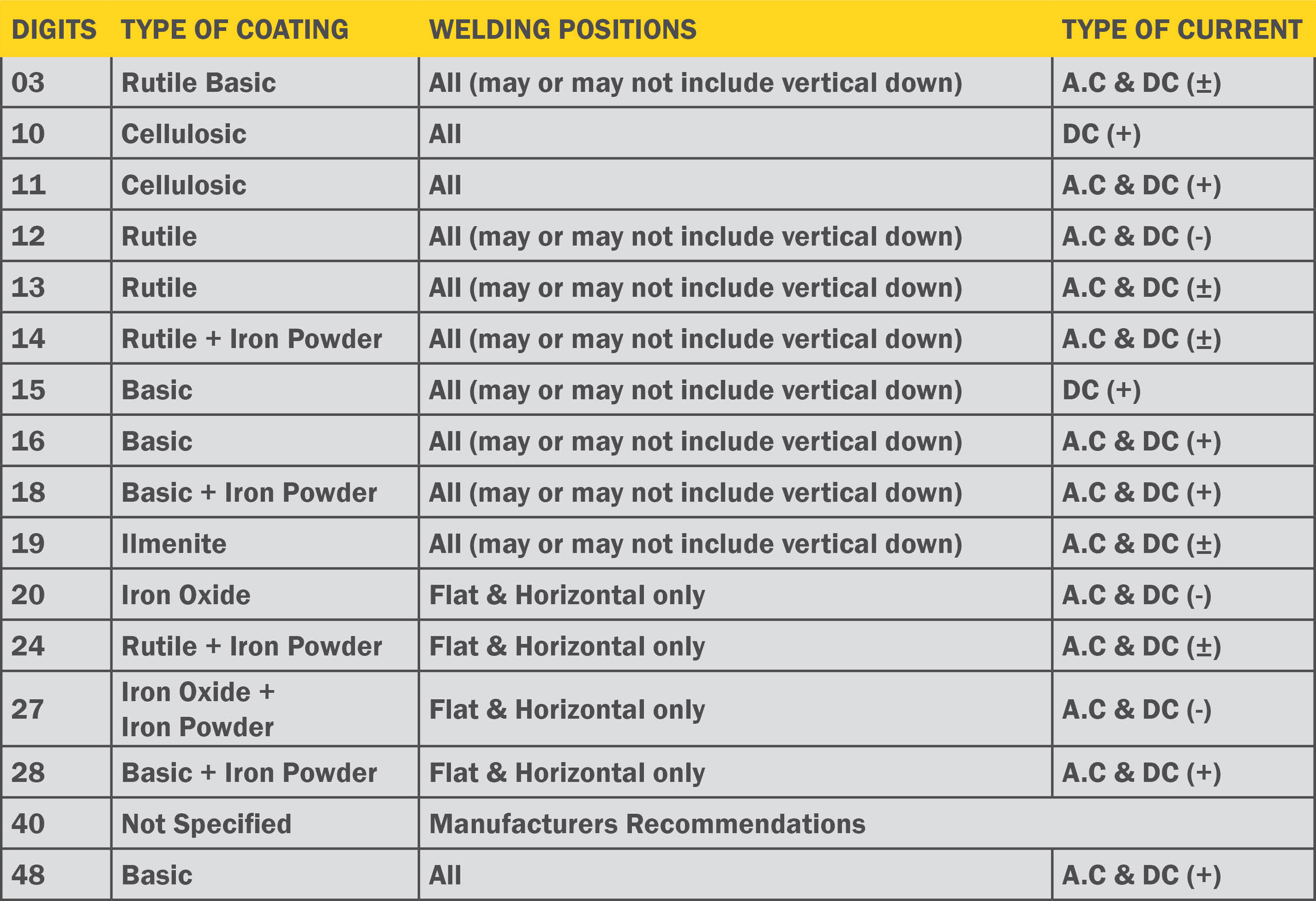

The electrodes have a coding system to identify them.

Free training on your own time.

A commonly used electrode for mild steel is er 70s 2 er stands for electrode or filler rod.

Tig stands for tungsten inert gas named from the tungsten electrode and the shield of inert gas argon or argon mixture surrounding it.

Product demonstrations welding tips and more.